Applications

- Odour Source Identification and Support of industrial Odour Management

- Sub-ppm Sulfur Quantification

- Propellant Gases Testing

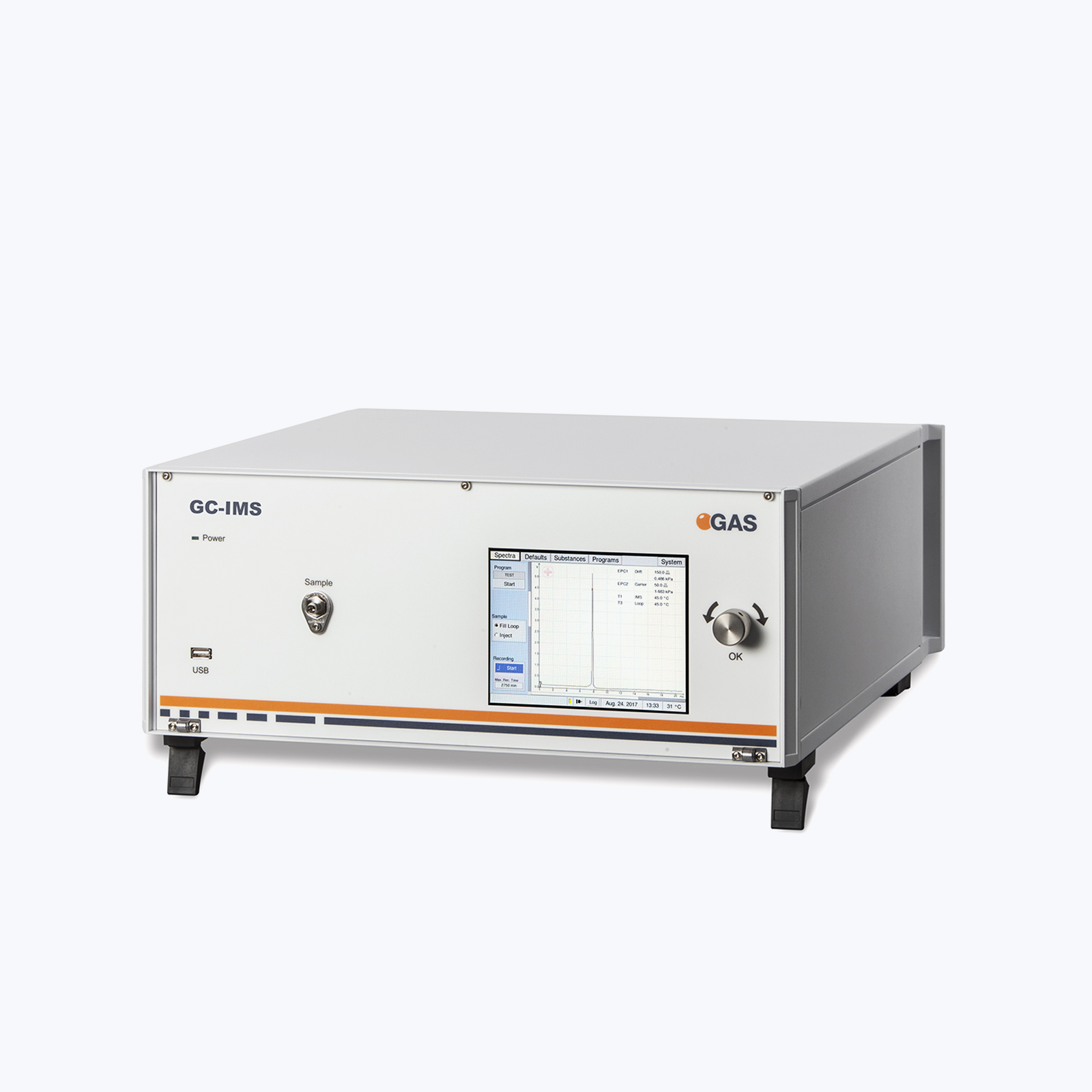

The GC-IMS operates isotherm in a range of 40-80°C and >100°C for baking out (cleaning). The GC-IMS provides an automatic data acquisition on the device and when connected to a PC 3-D data visualization and analysis by G.A.S. software suite called Laboratory Analytical Viewer (LAV). Besides the possibility of quantifying single marker compounds additional software plug-ins allow to easy detect the appearance of new compounds or the differences of concentrations of existing compounds. The result classifies differences from a selected reference (golden standard) to quickly characterize e.g. the quality of a sample.

An easy menu, manual or automatic operation modes as well as data acquisition, -analysis on board plus analogue data output via 4-20mA current loop facilitate a remote online process control. While the standard configuration of the GC-IMS requires N2 or synthetic for its operation it can alternatively be equipped with a circular gas flow unit (CGFU) to be independent from any external gas supply. All these characteristics together represent highest flexibility and make up the usefulness of the GC-IMS as analytical online and/or on-site tool.

Through this the device can be applied for several analytical measurements e.g. testing for residual solvents, impurities from production, off-flavour detection, product or ingredients authentication, bad smell or TICs monitoring from industrial plants, perfume and cosmetics on human skin, etc.

ΠΕΡΙΛΑΜΒΆΝΕΙ

- Stand alone operation due to integrated computer unit

- High reproducibility

- Heating mode up to 100 °C for fast cleaning of the system